THE OPTIMAL BALL DIAMETER IN A MILL .

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

· Ball mill,like hammer crusher, and impact crusher, grinds material through the rotation of a cylinder with steel grinding balls, which cause the balls to fall back .

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Ball Material Selection What ... It is more susceptible to stress cracking during the quenching cycle of ... fine toothed, mill bastard file. Hold the ball to be ...

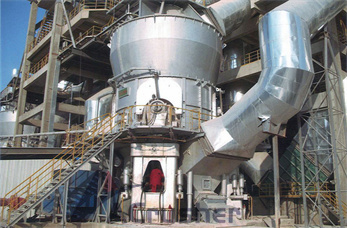

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

The Selection and Design of Mill Liners . ... High–low double wave ball mill liners – These are a refinement of the wave liner, ... material used for SAG mill liners.

Cement grinding Vertical roller mills versus ... to the ball mill system and has increased ... vertical roller mill takes place by exposing a bed of material to a ...

PATTERSON Batchtype Ball Pebble Mills. ... distillation and recovery of solvents may all be accomplished during the grinding operation. Gas ... Ball Mill without ...

Material During Ball Mill. If you want to get more detailed product information and prices, ZME recommend that you get in touch with us through online chat.

The results of a detailed study on material flow through a gratedischarge (openend) ball mill versus an overflowdischarge (constrictedend) ball mill are presented ...

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

How to Use a Ball Mill Safely and Effectively I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal.

material during ball mill. MQ Ball Mill VFLO Milling means milling with concentrate and water. The green ball strength is increased because of the process.

Introduction of Ball Mill – Material Articles. Ball mill is used to grind all kinds of mines and other materials and is widely used in mineral separation, building ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill.

also be introduced to the mill during ... The critical speed of a ball mill is ... A good starting point for material loading is to have enough material in the mill ...

Quick Easy Black Powder Ball Mill ... (this article contains an animation of what the contents of a ball mill do during operation): ... and material to be milled, ...

material [3,4]. A mill is a type of rotating or ... the speed at which the mill load sticks to the walls of the mill during ... size ball mill was used with ball ...

Synthesis of Nanomaterials by High ... It is a ball milling process where a powder mixture placed in the ball mill is ... During the highenergy ball ...

Energy dissipation during the impact of elastic–plastic ... the material of contact bodies ... R is the radius of tumbling ball mill. During the grinding process, ...

Magnesium–carbon hydrogen storage hybrid materials produced by reactive ball ... in the material during the milling is ... of Retsch ball mill ...

Global grinding industry high end wear resistant material suppliers. info ... We have 15 sets of grinding steel ball ... improving the production capacity of ball mill;

WhatsApp)

WhatsApp)