Iron ore pelletizing

Process overview. Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Process overview. Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be ...

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden ...

Made from high quality, natural deposits of limestone, and meeting exacting chemical and physical properties, Carmeuse has a broad range of lime and limestone ...

The function of the limestone. Iron ore isn''t ... the basic oxygen process. Impurities in the iron from the Blast ... Types of iron and steel. Cast iron has already ...

Limestone is a chemical or biological sedimentary rock that has many uses in ... this evaporative process can result in an accumulation of icicleshaped calcium ...

Limestone is a chemical or biological sedimentary rock that has many uses in agriculture and industry.

Steel Recycling Steel has been produced in various forms for 3,500 years. Modern steel is manufactured from iron ore with ingredient such as coke, limestone, manganese,

with the contents of iron ore, limestone and ... This process is used ... limestone in pig iron process Milling is also known as grinding, it is a material more refining process. A sharp object works by concentrating forces which creates a high pressure due to the very ...

The pig iron, limestone and iron ore go into an openhearth furnace. ... Another way to create steel from pig iron is the Bessemer process, ...

The ore is loaded into a blast furnace along with measured quantities of coke and limestone. Hot combustion air is supplied to the furnace and some form of fuel used ...

Steel making; Steel making. Carmeuse ... chemical grade limestone is put to use in four iron making ... and utilized in the sinter process to help flux iron ore and ...

Process. Ore, limestone and carbon in the form of coke are put into the top of the blast furnace in layers. At the same time, hot air called "wind" is blown inside ...

Limestone: Characteristics, Uses And Problem Procedure ... may be absorbed into the stone and during the normal process of ... be based on either iron or ...

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron, but also others such as lead or copper.

Limestone is a sedimentary rock, composed mainly of skeletal fragments of marine organisms such as coral, forams and molluscs. Its major materials are the minerals ...

The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore

Iron and Steel: a trip inside a steel mill. ... The process of refining molten iron with blasts of air was ... Without the limestone, iron silicate ...

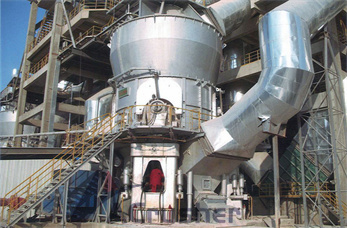

Iron Ore Pellets and Pelletization Process. Pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in ...

The most common process is the use of a blast furnace to produce pig iron which is ... to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. .... A byproduct of iron purification is slag, which is produced in huge amounts.

Jun 11, 2009· limestone used as a flux which is used to remove impurities (such as silica (SiO2)) in the ore to forms a slag which melts and collects above the iron at ...

Galvanized iron sheets. Galvanization is the process of applying a protective zinc coating to steel or iron in order to prevent it from rusting.

Iron Ore Smelting Process Using Modern Blast Furnaces. ... with the contents of iron ore, limestone and coke being carefully measured, ...

Limestone Quarrying and Processing: A LifeCycle Inventory ... LCI INPUTS FOR LIMESTONE QUARRYING AND PROCESSING ... Process flow diagram for limestone .

Limestone is used in a wide variety of products it is one of the most widely used rocks.

WhatsApp)

WhatsApp)